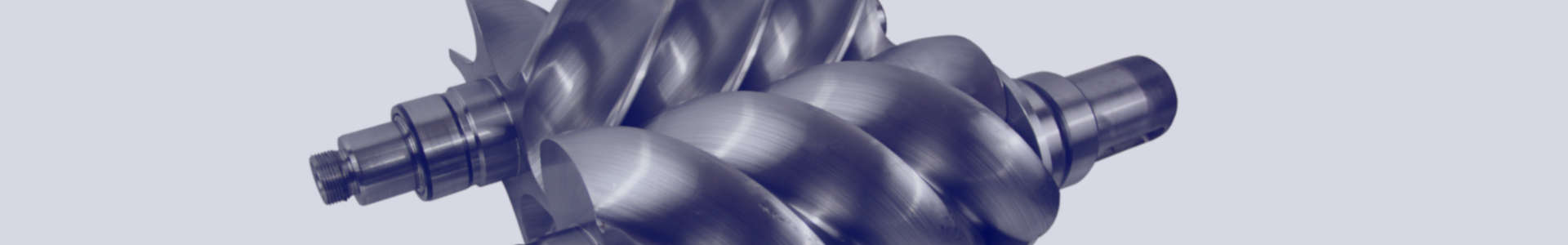

ALLEGRO compressors with direct drive & frequency converter

Allegro screw and energy-saving compressors meet high standards for compressed air production. Depending on the design, these compressors have an engine power of 8 - 315 kW and a maximum pressure of up to 13 bar. Continuous speed control ensures precise power adjustment, minimizes equipment wear and possible energy savings of up to 30%. For example, variants with variable engine speed, frequency converter or also with recuperation technology are available, which can effectively process waste heat and use it for water heating by up to 75%. These features of the device lead to economic and ecological advantages. The compressor design was designed to ensure easy service and maintenance in the future and withstand harsh conditions.

Possible configurations

- Standalone compressor

- Compressor on air tank 270 – 500 liters

- Compressor on air tank with condenser dryer

Accessories

- Integrated condensate separator (for variants in combination with integrated dryer)

- Coarse and fine filter with mesh insert for removing dust and oil particles 0.1 microns (for variants in combination with integrated dryer)

- Control unit for a higher level of operation monitoring and control

Benefits

- Easy commissioning, easy service and maintenance

- Variety of configurations

- Integrated handling handle for forklifts

- Reduced noise

- Direct drive ensures 3% more efficient operation compared to belt compressors

- Recovery technology

- E-series focused on energy savings

Downloads

- alup-largo-allegro-11-22-e-en_lr_6999640440-00503.pdf [PDF, 7.7 MB]

- alup-largo_allegro_132-315_leaflet_-en_6999640381-0bf71.pdf [PDF, 2.76 MB]

- alup_allegro_8-14_leaflet_en-df3c6.pdf [PDF, 3.66 MB]

- alup_largo_-allegro_23-36_leaflet_en-f6cae.pdf [PDF, 5.21 MB]

- alup_largo_allegro_31-110_leaflet_en_6999640302-f1206.pdf [PDF, 6.38 MB]

- ipm_brochure_a4_alup_eng_200820-efd03.pdf [PDF, 3.62 MB]