SFD sub-freezing dryer -20°C PDP, class 3 ISO8573-1

Sub Freezing Dryers - SFD Series - Regenerative refrigerant dryers

The revolutionary SFD dryer is currently the only - 20°C PDP refrigerant dryer available on the air treatment portfolio. It combines the subfreezing pressure dew point of a traditional regenerative adsorption dryer with the low functioning and energetic cost of a refrigerant dryer, offering an extremely reduced total cost of ownership.

High air quality, Class 3 ISO: 8573-1 with a -20° PDP - Delivered without any interruption throughout the whole working range, depending on the compressor.

Excellent - For sytems where piping or pneumatic equipment are exposed to subfreezing temperatures.

Patented heat exchanger - With a double cooling chamber and a pre-cooler / re-heater that provides a subfreezing pressure dew point, reducing functioning and energetic costs.

No purge air needed - For the regeneration, with remarkable improves in the energetic efficiency.

No expensive consumable - Such ad drums or dessicant media that need to be changed, reducing the cost of maintenance.

Innovative controller - Which ensures an high air quality and, thanks to his intuitive and high definition display, allows to monitor the performance. Moreover, it is equipped with a remote connection with Internet browsing and a SD card that stores constantly the I/O of the dryer.

Easy to install - Footprint reduced of the 40% compared to a corresponding adsorbing dryer and complete match with all compressors, without any need for expensive change outs or previous particle filtration.

Smart exhaust valve - Which works differently according to the demand, to guarantee a complete clearance of water in every cycle.

Standard features

Removable panels for easy inspection and maintenance

Electric protection IP42

Electronically actuated smart solenoid drain valves (no-loss drain)

with electronic feedback to the controller

Programmable controller

Victaulic© fittings for and easy maintenance

R452A refrigerant gas

Optional

Kit for low ambient

Kit for inlet temperature

External modification/IP54 protection

The SFD dryer uses the refrigerant instead of the desiccant media in the drying process. This peculiar approach offers different benefits, which make the SFD dryer perfect for compressed air applications needing a Class 3 dried air with a -20°C pressure dewpoint.

Improved energy efficiency - Typical desiccant dryers use upwards of 15% purge air for regeneration, which equates to 15% of the energy cost of the compressor. The SFD dryer does not require purge air, eliminating this wasted energy cost.

Lower maintenance costs - The SFD dryer has no costly consumables that require periodic replacement such as drum wheels or desiccant beads. In addition, no external heaters or blowers are required for regeneration, reducing the need for highmaintenance equipment. Easy to install With a 40% smaller footprint, the SFD dryer uses less floor space and is fully compatible with all compressor types (both oil-flooded and oil-free) without requiring any costly modifications to the air compressor or downstream particulate filtration.

Reduced equipment and operating costs - Since the SFD dryer does not consume purge air, 100% of the air supplied by the compressor is available downstream to the dryer. This eliminates the need to psize the compressor to compensate for the dryer’s purge requirements, saving both equipment and operating costs.

Versatility

Three options that make the SFD dryer suitable for all needs:

• Opt low inlet air temperature: extends working range up

to a minimum compressed air temperature of 5°C

• Opt low ambient temperature: extends working range up

to a minimum ambient temperature of -10°C

• Opt outdoor installation: allows the dryer to be installed

outdoor , sites protected by a roof, thanks to the IP54

electrical protection level.

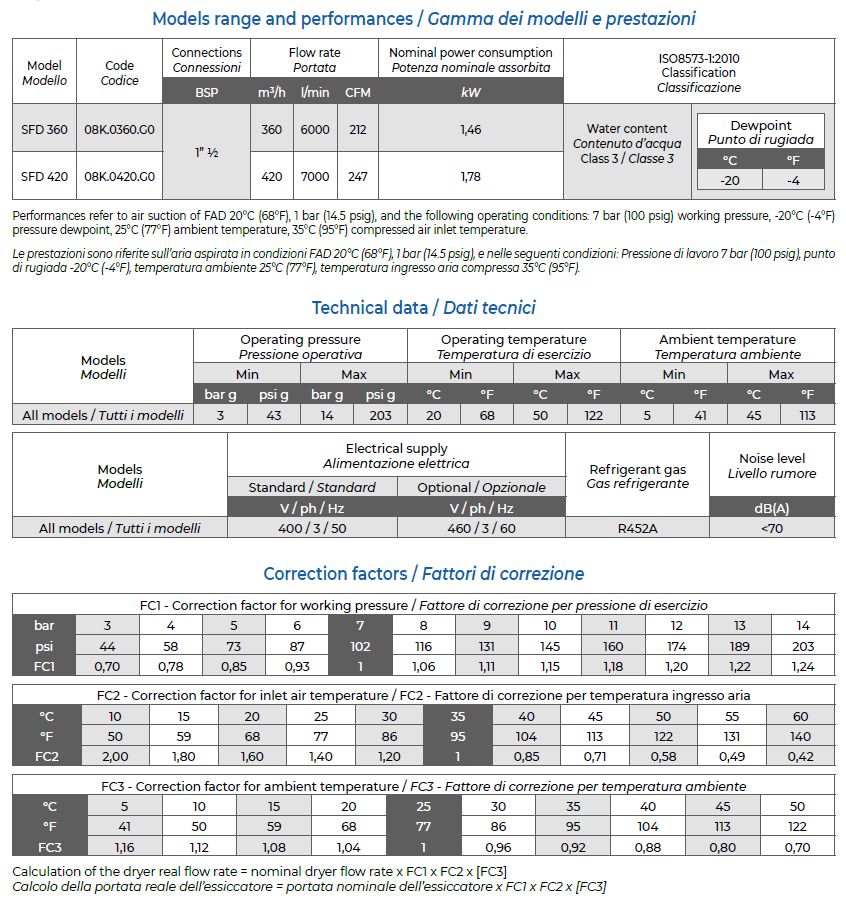

Downloads

- sfd_dryers_omi-0e5f5.pdf [PDF, 649.51 KB]